These are common problems and solutions when using ball mill.

Problem 1: When the ball mill is running, there is a very frequent hitting sound and the sound is also very large.

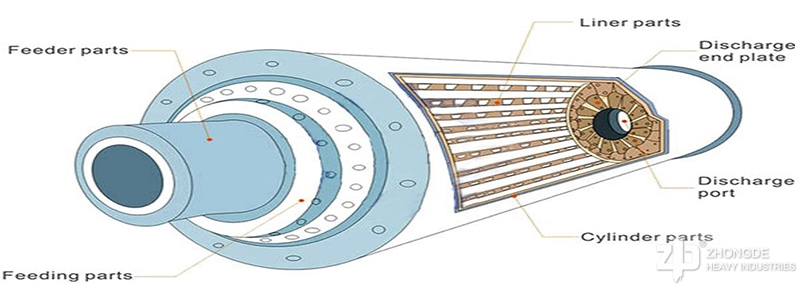

Solution 1: It should be that some of the lining bolts are not tightly screwed. The solution is that you can judge the ball lining by the sound of the machine, then find the loose bolts and tighten them.

Problem 2: When the temperature of the ball mill and its motor bearing rises above the specified standard.

Solution 2: You can test whether the bearing is partially or completely overheated by hand, then you can check the condition of the ball mill from the following aspects.

(1) Check the lubrication points of each part of the ball mill. The lubricating oil grade used is consistent with the factory manual.

(2) Check if the ball mill lubricant and grease are deteriorated.

(3) Check if the lubrication line of the ball mill is clogged, or the lubricating oil does not directly enter the lubrication point, and the oil quantity is insufficient to cause heat.

(4) The side clearance of the ball mill bush is too small, the gap between the bush and the shaft is too large, and the contact points are too much to form a uniform oil film on the bearing bush.

(5) The ball mill rolling bearing has too much or too little grease, and excessively formed rolling elements agitate the grease to generate heat, and the heat is not easily dissipated. If the lubrication is too small, the amount of oil should be increased according to the regulations, which is generally 1/3 to 1/2 of the bearing clearance.

(6) The sealing device of the hollow shaft at both ends of the ball mill body is too tight or the sealing body iron member is directly in contact with the shaft.

PS: The above problems will be dealt with according to the reasons. Only if the side clearance of the bearing bush is too small, or the bottom contact angle is too large, the grinding cylinder body must be jacked up with a hydraulic jack, and the bearing bush is pulled out from one side of the shaft, and the tile is separately scraped.

Problem 3: Ball mill reducer bearing heat.

Solution 3: You can check according to the method of checking the ball mill bearing too high, you can also check whether the vent hole of the reducer is blocked, and often clear the vent.

Problem 4: After the ball mill motor with the reducer is started, the main causes of sudden vibration are as follows:

(1) The two-wheel clearance of the ball mill coupling is too small to compensate for the amount of turbulence caused by the self-seeking magnetic center when the motor is started.

(2) The correcting method of the ball mill coupling section is incorrect, causing the two axes to be different.

(3) The coupling bolts of the ball mill coupling have no symmetrical tightening and the degree of tightening force is different.

(4) Ball mill bearing outer ring loose.

Solution 4: adjust the wheel gap according to the specified, so that the two axes are concentric. Tighten the coupling bolts of the coupling symmetrically with the same torque. When the rotor is unbalanced, the ball mill rotor is taken out to find a static balance.

Problem 5: When the ball mill reducer drives the mill, huge vibration occurs.

Solution 5: (1) The balance shaft of the ball mill and the reducer, the axis is not in the straight line, the reason is: when the mill is installed with the lining, no secondary grouting is performed, or the anchor bolts after the secondary grouting are not fastened, and the grinding cylinder is rotated by the hoisting machine, so that one end of the grinding cylinder is displaced, and the two axes are not in a straight line. The vibration is generated after the reducer drives the mill. To re-adjust, make the axis of the ball mill and the axis of the reducer on the same plane axis.

(2) The large ball mill is bulky and heavy, causing the foundation to sink; displacement occurs. Monitoring settlement points are set up next to the foundation; observations are made and adjustments are made when there is sinking.

Problem 6: The sound of the ball mill reducer is abnormal.

Solution 6: The sound of the normal operation of the ball mill reducer should be even and stable. If the gear has a slight knocking sound, the hoarse friction sound, there is no obvious change during the operation, you can continue to observe, find out the reason, stop the ball mill and deal with it; if the sound is getting louder, you should immediately stop the ball mill for inspection.

Contact Us

Tech Guide: Chat Online (24/7 Service)

Email: sino@zdzg.com

NOTE: please feel free to fill out the form below in detail and you can also send a message to us(sino@zdzg.com), we will send you latest price within 24 hours.Besides, you can click Chat Online on the right hand side to get quotation online